Study of Coupled Thermo-Hydro-Mechanical (THM) Behaviour of Rock Related to Geothermal Industry

Australian contains one of the hottest granite on earth at reasonable drilling depth and Hot Dry Rock (HDR) geothermal energy is considered as a practical prospect in the future. This project aims to study the mechanical behaviours geothermal reservoir rock at the deeply buried earth. Temperature, pressure and fluid flow forms a complex mechanism that can be extremely differs from the surface rocks. A large amount of experimental works have carried out and the results will contribute information for the development of guidelines for engineering design at depth, including the rock physical property (mineralogy, grain size and porosity) dependence, temperature dependence and pressure dependence. Besides, a new multiphase high pressure and temperature controlled triaxial testing apparatus for geomaterials is designed and constructed in purpose of simulating the actual underground condition. This apparatus allows confining pressure up to 130 MPa, temperature up to 400 °C and fluid injection of 160 MPa, with axial loading capacity of 10 tonnes.

CO2 sequestration in deep saline aquifer: A study of factors affecting the hydro-mechanical properties of saline aquifers in CO2 sequestration

Carbon dioxide (CO2) is one of the main greenhouse gases released to the atmosphere mainly from the burning of fossil fuels, such as coal, oil and natural gas, which currently supply around 85% of the world’s energy needs. Moreover, due to the low relative cost and abundance of fossil fuels, it is likely that fossil fuels will govern the economy for at least the next 25 to 50. Therefore, it is necessary to have proper CO2 emission control techniques to create a safer atmosphere for human beings. Geosequestration of carbon dioxide (CO2) in deep saline aquifers is one of the most feasible approaches to mitigate global warming. However, dissolution of injected CO2 in brine has some effects on chemical diffusion, failure strength and permeability in the reservoir rock. There is also a significant variation in the mineral composition of reservoir rock upon exposure to CO2, which changes the mineralogical and micrological structure of the rock mass and consequently changes the hydro-mechanical properties of the rock. Therefore, this research provides a comprehensive study of the potential changes in aquifer mechanical properties and permeability characteristics caused by injected CO2 under in situ conditions, highlighting the factors affecting the integrity of sedimentary rock properties.

In this research work, basically the following methods will be used;

- Laboratory experiments high temperature and high pressure tri-axial set up.

- Acoustic Emission (AE) to study crack propagation strength thresholds.

- Numerical modelling (COMSOL) to study the flow and strength behaviour of reservoir rock under different pressure and temperature conditions. These modelling results will be compared with laboratory experiments.

- Empirical modelling to improve the existing formula for reservoir rock failure strength, to suit deep underground conditions (pressure, temperature and fluid medium)

Core flooding experiments on CO2 geological storage

In recent years, the extreme weather caused by global warming has induced a number of meteorological and environmental disasters. Geological storage of CO2 is widely accepted as an effective method for reducing greenhouse gas emissions. Suitable geological formations for CO2 capture and storage include saline aquifers, coal seams, and depleted oil/gas reservoirs. Saline aquifers are common worldwide and have great potential for CO2 storage. CO2 injection and storage in deep saline aquifers involves many types of phenomena, and the main trapping mechanisms in deep saline aquifers are stratigraphic and structural traps, residual gas traps, dissolution, mineral precipitation, and/or adsorption. CO2 injected into an aquifer will displace the brine but because of capillary forces, the groundwater will not be completely displaced by the injected CO2. This remnant water has an important influence on the potential capacity and security of geological storage reservoirs. Residual water saturation will not only have a strong influence on the residual gas traps but also diminish the trapping capacity of structural and stratigraphic traps. Therefore, it is essential to carefully investigate the properties of residual water to improve our understanding of the conditions relevant to those seen in deep saline acquires. We conduct core flooding experiments to define the kind of saline aquifers most suitable for the geological storage of CO2.

Research on the mechanism of water inrush and numerical simulation

The karst conduits and faults encountered in underground engineering maybe filled with various materials, such as clays, sands and gravels. The fluid flow and the mechanism of water inrush from these structures are ambiguous and complexity.

Water can diffusion in the clays with low permeability and flow in the sands with high permeability, whereas water fluid in the gravels maybe become turbulence flow. Different fluid laws, such as Darcy Law and Brinkman Equation, need be applied to describe the water fluid in these filling materials. In addition, the mechanisms of water inrush are also different. When the faults and karst conduits are filled with clays, the whole filling structure may be slipped under the high water pressure. When the faults and karst conduits are filled with sands, the filling structure would become instability whose modes may be similar to piping, contact scour and soil flow.

This project would develop a theory on the mechanism of water inrush from faults or karst conduits, as well as modify existing code and incorporated to the software. Especially, develop a software based on the MATLAB platform and the Lattice Boltzmann Method (LBM) to analyze the mechanism and process of water inrush. Compare the results derived by the developed software and others business software, such as COMSOL, UDEC and PFC, to verify the feasibility and accuracy of the developed software.

Stimulation of Heat Extraction from the Hot Dry Rocks- Geothermal Energy

There is an enormous potential for power generation with geothermal energy however, at present commercial geothermal energy production is limited conventional geothermal resources. Enhanced or engineered geothermal systems (EGS) are considered unconventional geothermal resources which adapt engineering techniques to enhance the factors affecting geothermal energy production. Considering EGS systems, hot dry rock (HDR) systems are identified as potential geothermal resources which are primarily consist of granite with high temperature but very low permeability and little amount of stored fluid. Therefore stimulation techniques such as hydraulic fracturing, acid fracturing are adapted in order to enhance the permeability of the rock. Higher flow rate and thermodynamic efficiency of the circulation fluid determines the economics of the EGS. It is important to create interconnected fracture network with high transitivity for higher flow rate and sufficient residence time with contacting hot dry rocks. However, it is a real challenge to maintain both conditions together. Large volume of interconnected fracture network with small aperture and circulation fluid with favourable heat transmission characteristics is important to achieve this requirement. Considering the previous attempts of EGS development in the world, water has used as the fracturing and heat transmission fluid however, there are number of problems associated with water such as scarcity of water, contamination problems and higher solvent capacity of rock minerals at elevated temperatures which result reduction of fracture permeability with time. Therefore, non-water based fracturing fluids for reservoir stimulation has attracted geothermal community and supercritical CO2 has identified with favourable thermodynamic properties. Further, numerical simulations have confirmed that advantages of CO2 over water in terms of higher energy extraction rates. However, performs CO2 as fracturing fluid, geochemical issues as a result of aqueous solutions of CO2, structural changes associated with rock fluid interactions under geothermal conditions are poorly understood.

Therefore, this project aims to understand the coupled effects of hydro-thermo-mechanical and chemical behaviour of granite at geothermal conditions with hydraulic stimulation with water and super critical CO2 as a working fluid and further, to understand optimum conditions to enhance permeability with hydraulic stimulation with water and scCO2. This study is consist of a series of experimental works to address these issues; which utilize the newly developed advanced high pressure and high temperature tri-axial set up available in the 3GDeep Laboratory. Tri-axial experiments will be conducted for different granite rock, at various temperatures (20 to 300◦C), confining pressures (up to 150 MPa) and water and scCO2 injection pressures (up to 150 MPa) by simulating different geothermal conditions and rocks at different depths. In addition, to understand the chemical interactions between granite scCO2 and water at geothermal conditions, detail chemical and mineralogical study will be conducted with SEM, XRD, XRF and ICP-MS/ AES analysis. Also, the CT scanner and SEM analysis will be used to study the pore structure variation due to water and CO2 injection into the sample under various test conditions.

This knowledge is then used to develop theoretical and empirical equations for strength criteria and flow behaviour of fractured rock incorporating temperature and pressure influence. Firstly, a lab scale model will be developed to study the mechanical and flow behaviour of granite under tri-axial tests conditions and it will be extended to a more comprehensive coupled thermo-hydro-mechanical model which simulate the field condition. Findings of this study will contribute to unconventional EGS technology and Australian economy which seek novel approach for commercial EGS energy production.

Proppant degradation mechanisms on hydraulic fracturing in shale reservoir

Shale reservoir has been proved to have large storage of energy resource. By the commonly-used hydraulic fracturing process, proppant is taking an essential role to keep the fracture open after pumping and its behaviour is strongly related to the hydraulic conductivity and production rate. However, several proppant impairment mechanisms, including proppant diagenesis, proppant embedment, proppant flowback and fine generation & migration, have strong detrimental effect on proppant behaviour, which directly causes the reduction fracture width and the subsequent influence on hydraulic conductivity and production rate.

This study focus on major proppant impairment mechanisms to figure out the influence of different potential factors (like fracturing fluids, temperature, cyclic stress) on proppant behaviour. It is expected to achieve higher initial and lower reduction for both fracturing width and hydraulic conductivity by optimising the proppant behaviour.

Evolution of fluid flow system in the CO2-enhanced geothermal system: Experimental study on the mechanical and thermodynamic properties of granite minerals and molecular dynamics simulation

CO2-enhanced geothermal system would use the CO2 instead of water as heat transmission fluid, and it would achieve geologic sequestration of CO2 as an ancillary benefit. However, the microscale mechanical for the fluid-rock chemical and mechanical interactions are still ambiguous and unsolved.

Before the production of the geothermal well, artificially induced fractures is of significant importance for the permeability enhancement and reservoir stimulation. In the absence of thermal shock or high thermal gradients, thermal stresses are generated by two main mechanisms: (1) mismatch in thermal expansion coefficients between different minerals and (2) thermal expansion anisotropy within single minerals. Thermal expansion coefficient (both linear and volume) and its anisotropy can be gained through the quantitative phase analysis methods (Rietveld structure refinement using the software TOPAS) via powder XRD. After that, Particle flow code (PFC) will be adopted to investigate the fracture pattern of granite using the thermal expansion coefficient of each composite. This project would be beneficial at explaining the rock failure mechanisms under the impact of temperature (both high temperature and cryogenic temperature).

Molecular dynamics (MD) is a computer simulation method for studying the physical movements of atoms and molecules and it acts as a bridge between microscopic length and time scales and the macroscopic world of the laboratory. MD simulation can be adopted to study the mechanical and thermodynamics properties of granite minerals and the reservoir fluids. We have applied the LAMMPS to study the stress-strain curve of granite minerals and the corresponding Poisson’s ratio. Our next step is to construct the multi-phase crystalline mineral (granite or other reservoir rocks) and study the mechanical properties (basic mechanical parameters and fracture initiation and propagation). The interaction mechanism (diffusion, chemical reaction, interfacial tension, etc.) between fluids (water or supercritical carbon dioxide) and rocks will be spelled out after that. Experimental methods, for example, XRD, SEM, CT and nanoindentation will be adopted to validate our simulation results.

CO2 sequestration: A study of long-term stability of caprock sealing under deep saline co2 sequestration environment

Carbon dioxide (CO2) is one of the main greenhouse gases released to the atmosphere mainly from the burning of fossil fuels, such as coal, oil and natural gas, which currently supply around 85% of the world’s energy needs. Moreover, due to the low relative cost and abundance of fossil fuels, it is likely that fossil fuels will govern the economy for at least the next 25 to 50. Therefore, it is necessary to have proper CO2 emission control techniques to create a safer atmosphere for human beings. Geosequestration of carbon dioxide (CO2) in deep saline aquifers is one of the most feasible approaches to mitigate global warming. But in actual field condition, one of the major concerns of underground CO2 sequestration is the CO2 leakage through the caprock due to numerous reasons.

The injection and buoyancy pressure of CO2 can activate both fractures and faults in the caprock. On the other hand, the rock matrix porosity and fracture apertures (primary and secondary fractures) can be affected by chemical reactions (dissolution and precipitation) between CO2 and caprock minerals. As a result, in the long-term scenario there are possibilities of leaking CO2 through caprock. Therefore, it is very crucial to find the changes of chemico-mineralogical and hydro-mechanical properties of the caprock in the presence of CO2 in the long-term scenario. Such understanding can reduce the risks related to leakage of CO2 by selecting suitable sites and controlling the injection pressure and injection intervals etc. Therefore, this research is aimed to obtain a comprehensive knowledge on chemico-mineralogical and hydro-mechanical properties of the caprock in long-term scenario under deep saline CO2 sequestration environment by conducting experimental studies, numerical and analytical simulations.

Micro-level respond of coal associated with CO2 sequestration in deep coal seams

Geosequestration of CO2 has been identified as a promising technique to mitigate global warming. Deep un-minable coal seams are recognised as potential reservoir for CO2 sequestration, where great amount of CO2 can be stored and large volume of CH4 can be extracted during the process. However, injection of CO2 in coal seams will lead to its physical and chemical structure to be significantly changed, resulting in a modification of coal mass hydro-mechanical properties. Ultimately, these alterations will affect the safety and efficiency of the sequestration project.

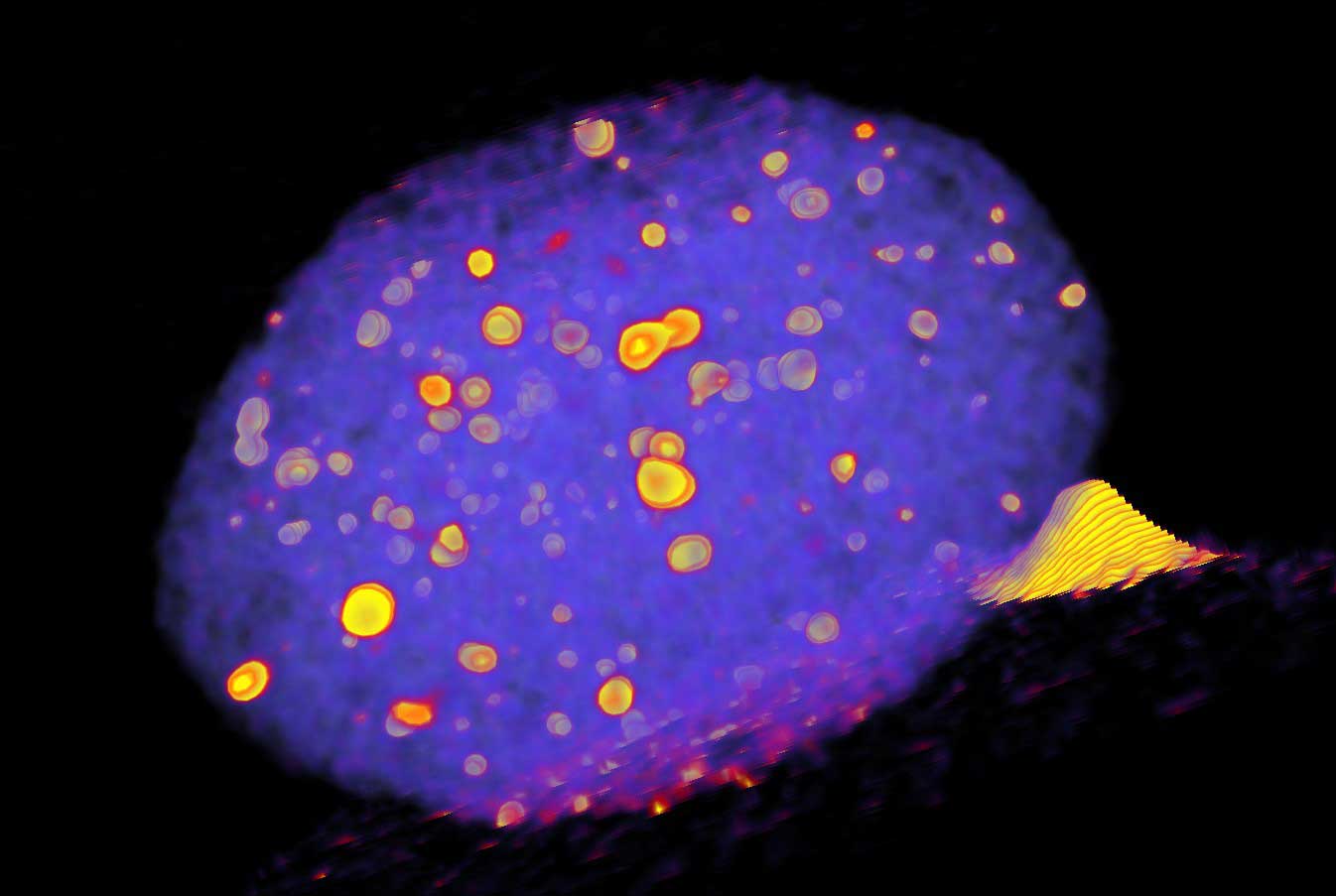

This project aims to characterize coal microstructural and mineralogical changes upon CO2 injection and investigate the resultant hydro-mechanical properties alteration under in-situ conditions. In-situ CT imaging will be conducted using X-ray triaxial cell to study the fracture network change of coal due to coal-CO2 interaction at reservoir conditions and lattice Boltzmann method will be applied on the micro-CT images to determine the flow behaviour variation. Chemical and mineralogical reactions will be studied by conducting SEM-EDS, XRD and ICP-MS analysis. Mechanical property change of coal will be determined by conducting UCS, P S wave and nano-indentation tests.

Numerical and experimental study of sand production in oil and gas reservoirs

Sand production is a phenomenon that occurs during the development of oil or natural gas in the petroleum industry. Sand particles in unconsolidated and weakly consolidated formations move from the reservoir into the well along with the oil or natural gas flow, which is commonly known as “sand production”. It is estimated that 70% of the world’s total oil and gas reservoirs are prone to sand production. Sand production may cause many problems including bore well failure, damage to safety valves, lifting equipment, surface equipment and pipes. Accurate prediction of sand production and destabilization of perforation cavities will be very helpful in selecting the maximum drawdown without sand control, perforation cleaning schemes and optimum well-completion methods. Therefore, a series of consequences arisen by sand production during oil or natural gas exploitation could be easier to avoid.

Numerical prediction of sand production is economic and efficient, compared to laboratory experiments. However, numerical simulation may obtain inaccurate or unrealistic results. It is necessary and important to validate sand production numerical model by field data, laboratory experiments and theoretical modelling, in order to ensure a realistic and consistent approach to sand production numerical prediction, which is the main object of this study.