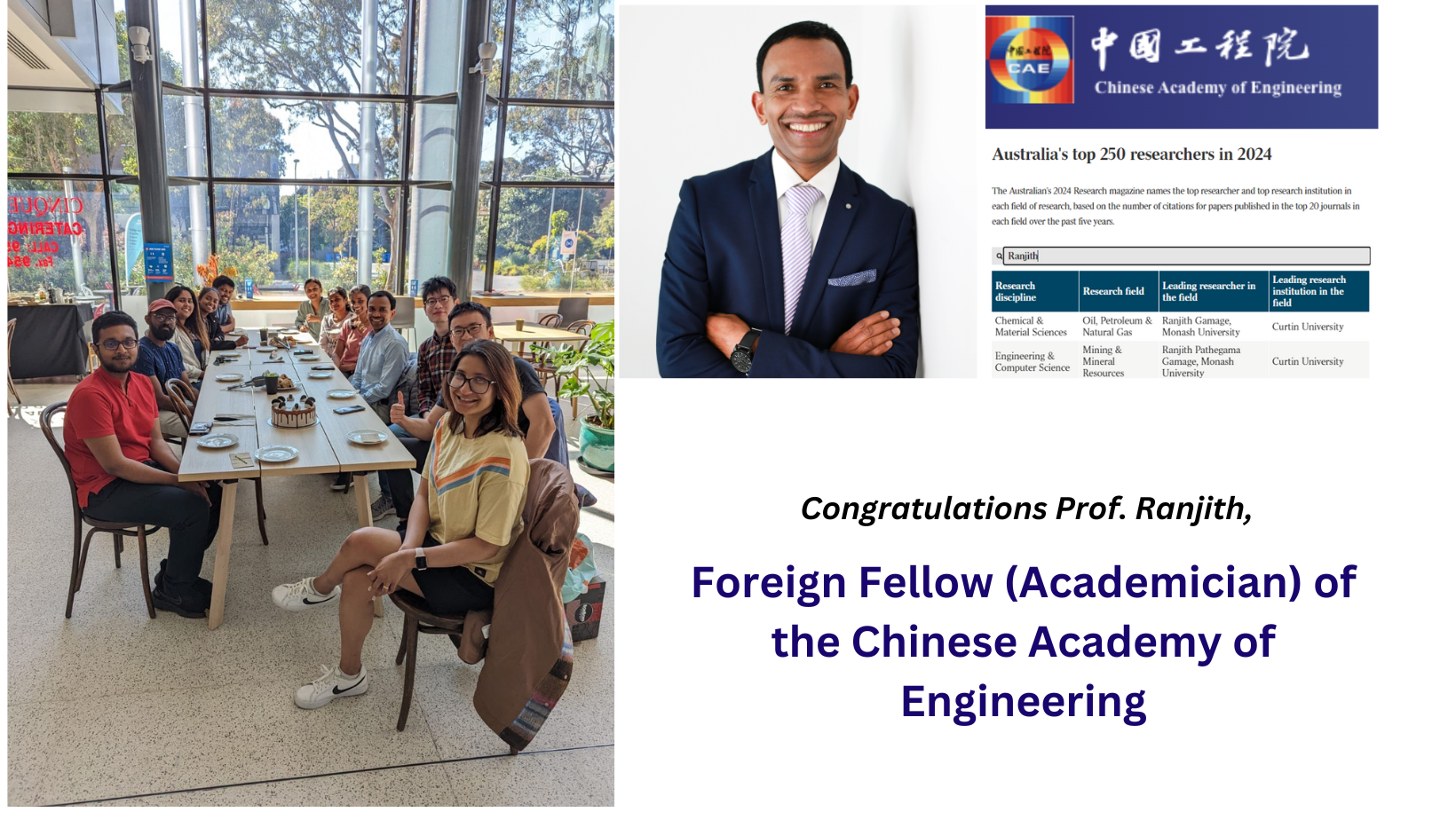

Foreign Fellow (Academician) of the Chinese Academy of Engineering

I am profoundly grateful and truly honored to have been elected as a Foreign Fellow (Academician) of the Chinese Academy of Engineering (CAE). This esteemed distinction reflects not just my personal efforts, but more importantly, the invaluable assistance and collaboration I have received from numerous colleagues, as well as my past and present PhD students and postdoctoral fellows. I wish to take this opportunity to extend my heartfelt thanks and appreciation to CAE colleagues and all those who have supported and contributed to my journey.

Prof. Ranjith is honoured as a Foreign Fellow of INAE

It is an incredible honour for me to be a Foreign Fellow of the Indian National Academy of Engineering and I would like to thank my colleagues/peers for nominating me to this prestigious body :Indian National Academy of Engineering.

This recognition is given to foreigners who have made outstanding contributions to “engineering which are of exceptional merit and distinctive eminence in new and developing fields of technology”. I first visited India in 2006, and since then I have continued to work with my colleagues in India from research institutions/universities (in the areas of Climate mitigations, Geothermal Energy, Resource Recoveries, Waste to Wealth etc).

Congratulations Dr. Samintha Perera - Dorothy Hill Medalist 2022

Our heartiest congratulations to Dr Samintha Perera for being awarded the prestigious Dorothy Hill Medal for her impactful research on the interactions between CO2 and coal mass in underground applications.

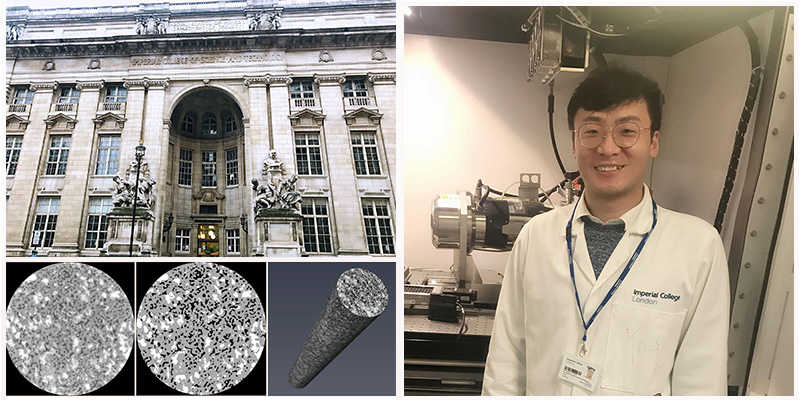

Congratulations Dr. Guanglei

Our warmest congratulations to Dr Guanglei Zhang for being appointed as a postdoctoral research associate at the Department of Earth Science and Engineering in prestigious Imperial College, London. He is working with Pore-scale Modelling and Imaging research group under Prof. Martin Blunt.

Congratulations Dr. Pabasara

Our warmest congratulations to Dr Pabasara Wanniarachchige for being appointed as a Lecturer in Geotechnical Engineering at the School of Civil, Mining and Environmental Engineering at the University of Wollongong, Australia.

Congratulations Dr. Radhika de Silva - Rocha Medalist 2022

We are pleased to share the wonderful news that Dr. Radhika de Silva, a former PhD student of the 3GDeep research group, was awarded the prestigious Rocha medal by the International Society of Rock Mechanics (ISRM) for the best PhD thesis in Rock mechanics discipline in the world.

The International Society of Rock Mechanics (ISRM) annually awards a bronze medal and a cash prize for the World Best PhD Thesis in Rock Mechanics in memory of Professor Manuel Rocha, the second President and organiser of the first international congress of the ISRM. The winning thesis is selected based on; 1) problem statement, 2) appreciation of state of the art, 3) theoretical and/or practical advancements, 4) verification of proposed solution and 5) quality of presentation of the thesis. The choice of the prize-winning thesis is the responsibility of the Rocha Award Committee, appointed by the President, chaired by the President, and including the Vice-Presidents and any others co-opted to assist in the review process. The committee then invites the Rocha Medal winner to attend the following ISRM conference as a guest to receive the award with providing all the expenses.

The first Rocha medal was awarded in 1982 and since then Australia could win it only five times (including this one) and one of these has been won by Dr P.M. Dight, from Monash University in 1985. After 29 years, in 2014, Dr. Samintha Perera, another former PhD student of the 3GDeep research group could bring that award back to Monash University. This time, the waiting was not too long as Dr. Radhika was able to bring this honour to Monash as well as to the 3GDeep research group.

Dr. Radhika is now working as the Humbolt fellow at Freiberg University of Mining and Technology, Germany and Umwelt- und Ingenieurtechnik GmbH, Dresden, Germany. He is also a Geotechnical engineer at Golder Associates, Australia.

Congratulation to Prof. Ranjith PG for receiving the Elsevier Scopus Award for Excellence in Sustainability

Digging deep for sustainable mining that mitigates climate change

During his 14 years at Monash, Professor Ranjith Pathegama Gamage has won a swag of innovation awards for his influential research into environmentally sustainable methods for extracting deep-earth resources like oil and gas that use carbon sequestration to combat climate change. His latest honour is a new Scopus Researcher Award from Elsevier for Excellence in Sustainability Research, which brings him a step closer to the ambitious goal that drives him. “My professional and personal goal is to contribute to our understanding of the world as responsible stewards of the planet,” Professor Ranjith says.

Professor Ranjith and his team pioneer creative, technically effective mining methods that often create useful by-products like fertiliser and green cement from waste. Their affordable, reliable method for extracting enhanced coal seam gas from otherwise un-mineable deep seams uses little water and releases methane for use while trapping carbon. This in turn has reduced carbon in the atmosphere, mitigating climate change, while transforming Australia’s abundant gas reserves into safe, sustainable energy.

“We know that over 80% of energy still comes from fossil fuel, and that fossil fuel will be the dominant energy supplier for at least few more decades,” Professor Ranjith says. “So we’re developing new technologies for unconventional gas like shale gas, tight gas and coal seam gas, which are very deep and difficult to extract, so they can be extracted economically and in an environmental friendly way.”

“Burying CO2 in deep underground is considered by many scientists and US engineering academics as the answer to large-scale reduction of CO2 levels in the atmosphere. It is one of the 21st century’s greatest engineering challenges”. Conventional mining is very energy intensive (over 10% of energy produced in the world is used for rock crushing and grinding) and therefore an alternate technology is required. In-situ leaching is a promising mining technology that can be enhanced by combination with suitably advanced rock-fracturing technology. We are now developing a disruptive technology-3G-DTM (3rd generation disruptive technology for mining-patent under pending) and the “results in the laboratory environment are very promising,” Professor Ranjith says. “I am confident that this technology will revolutionise mining in the future”. This 3G-DTM technology can be used in many other fields including renewable energy such as deep geothermal energy and unconventional oil and gas.

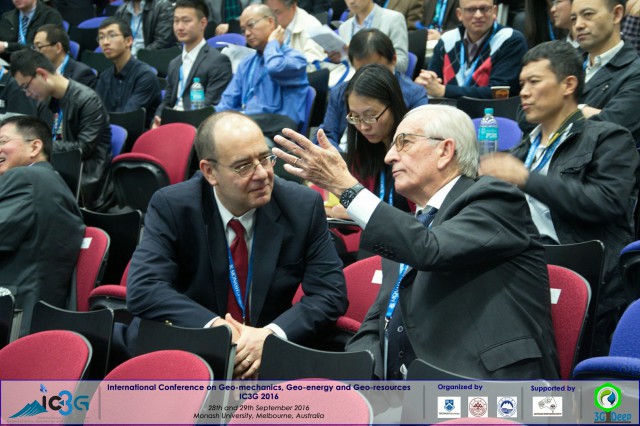

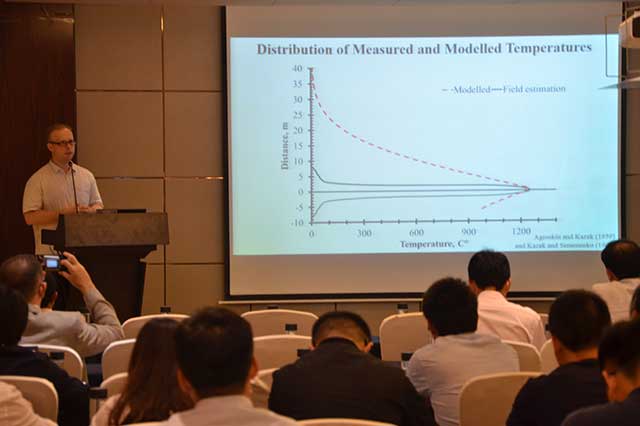

A huge success of IC3G 2016

The main goal of this 1st IC3G2016 conference was to bring together experts of Geoenergy and Georesources areas from Academia and Industry from the globe to discuss the challenges faced in those industries and to discuss and discover new sciences and to develop new technologies for economical and environmentally friendly methodologies for extractions of resources and energy from the earth. The conference was well over attended by 200 attendees

There were many topics (unconventional oil/gas, mining and petroleum geomechanics as well as civil geotechnical eng) covered during the two days of the conference, and the presenters did an outstanding job of sharing the latest research findings with other researchers.

The next IC3G 2018 will be held in Sichuan city, China in September 2018. The website (www.ic3g.com) will be launched very soon.

A huge success of IC3G 2018

The main goal of this 2nd IC3G2018 conference was to bring together experts of Geoenergy and Georesources areas from Academia and Industry from the globe to discuss the challenges faced in those industries and to discuss and discover new sciences and to develop new technologies for economical and environmentally friendly methodologies for extractions of resources and energy from the earth. The conference was well over attended by 200 attendees

There were many topics (unconventional oil/gas, mining and petroleum geomechanics as well as civil geotechnical eng) covered during the two days of the conference, and the presenters did an outstanding job of sharing the latest research findings with other researchers.

New stimulation strategy for unconventional reservoirs using foam

An interesting fact is that, according to the Department of Industry, Innovation and Science (DIIS), in the past ten years, the average annual growth of coal consumption in Australia decreased by 2% while that of natural gas increased by 4.1%. These statistics clearly illustrate that Australia is now transiting from coal to natural gas, considering the energy consumption. With these levels of dependence on natural gas, it is difficult to survive by only utilising conventional natural gas. Therefore, reservoir stimulation techniques need to be used in order to extract unconventional natural gases such as shale gas and tight gas. Of these technologies, foam-based fluid fracturing has the greatest potential to extract shale and tight gas effectively.

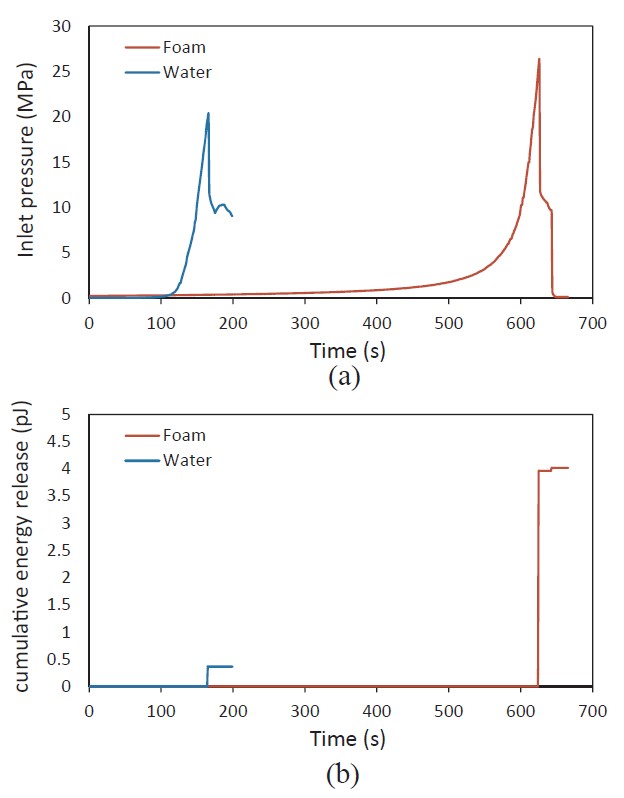

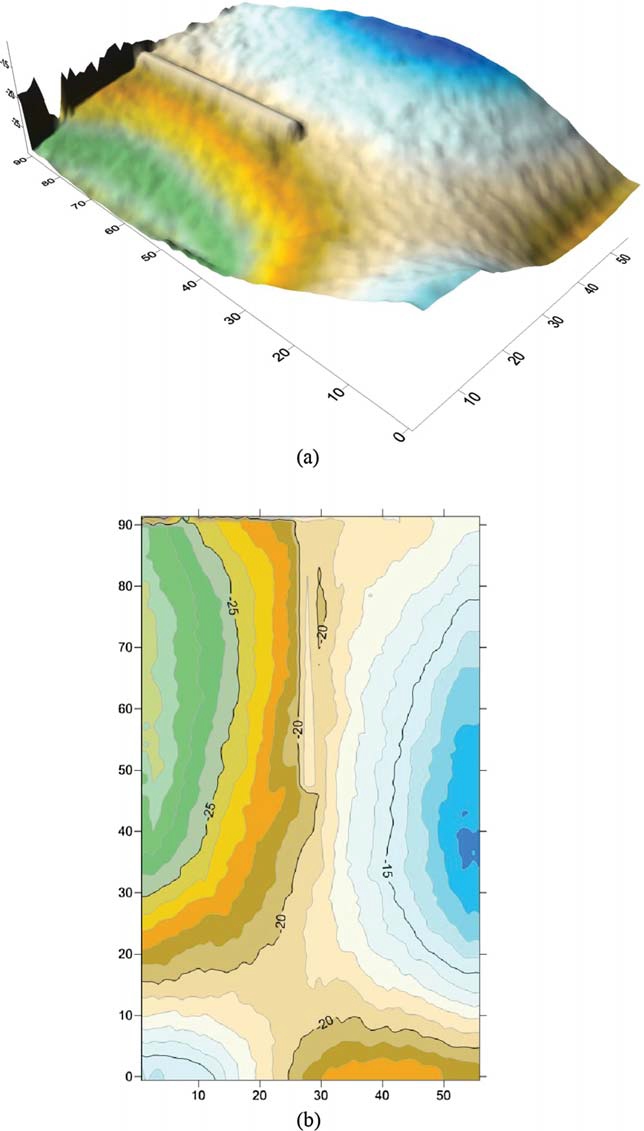

The recent studies reveal that, Foam-based fracturing fluid leads to a higher breakdown pressure of 26.3 MPa, which is about 29% higher than that of water (Fig.1). This is mainly due to the high viscosity of foam (150 mPa·s), which is about 200 times greater than that of water. Also the results show that the fracture pattern induced by hydraulic fracturing is significantly fracture fluid-dependent, and foam-based fluid generates a complex fracture with a twisted nature and higher fracture surface area compared to water (Fig.2). Therefore, the use of foam-based fracturing fluid is favourable for the extraction of greater amounts of natural gas. Moreover, the energy released in foam-based fracturing is about 10 times higher compared to conventional water-based fracturing, which is a favourable condition to enhance secondary and micro-fractures in the reservoir rock. This will enhance the productivity of the fracture treatment for natural gas production.

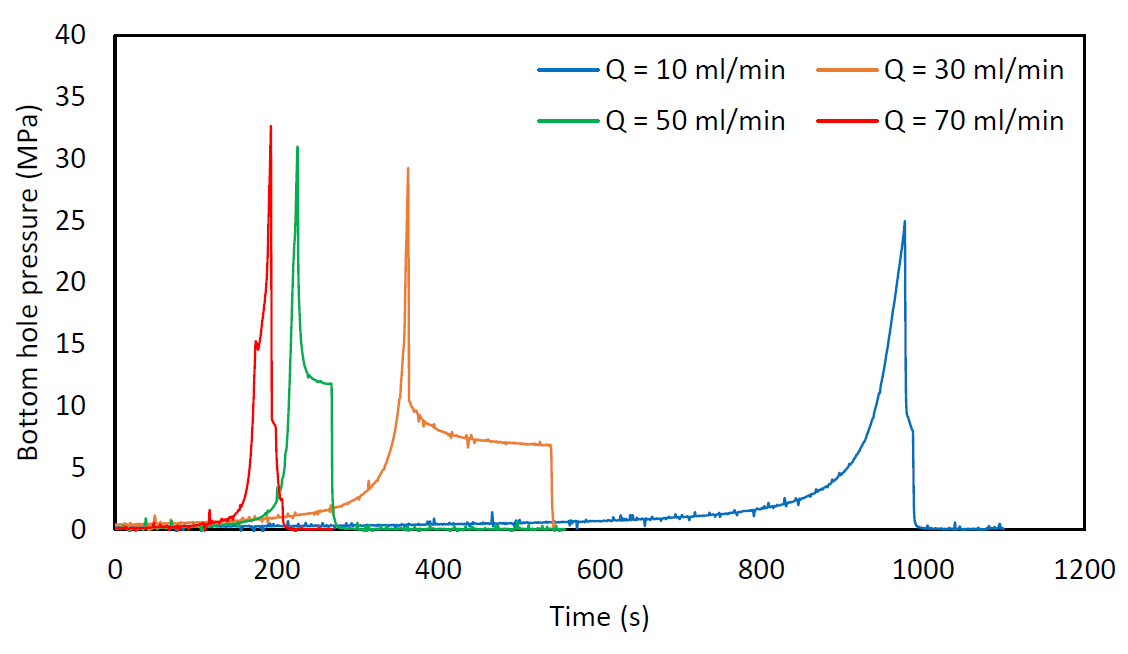

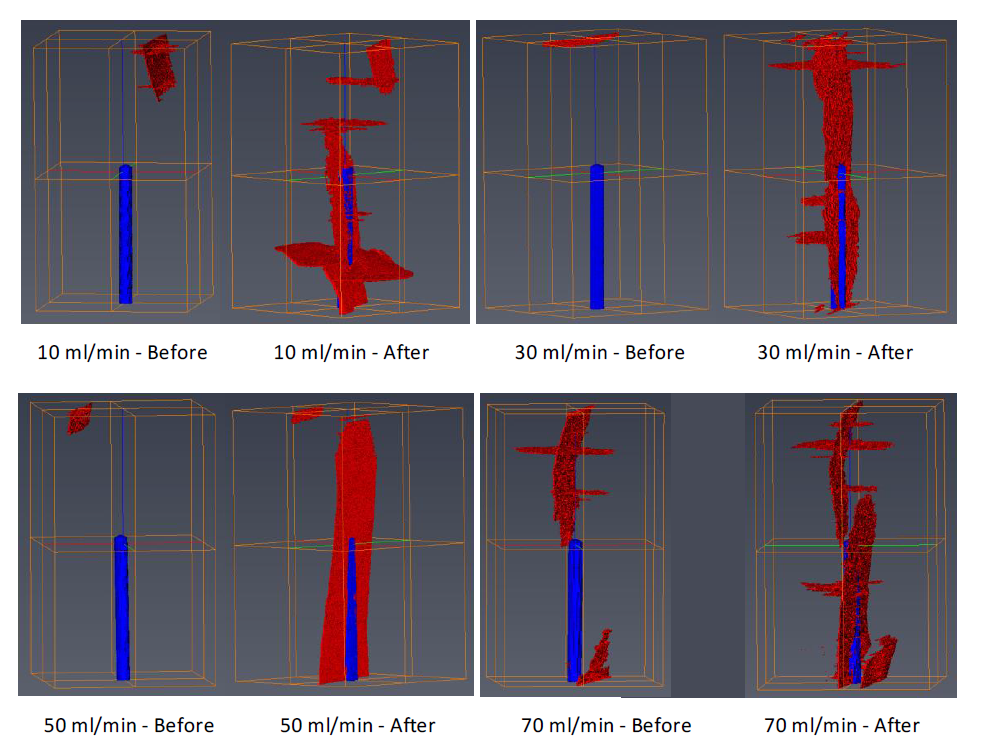

Experiments have been conducted using shale samples to investigate the effect of fracturing fluid injection flow-rate on hydraulic fracturing and associated fracture characteristics. Results reveal that the breakdown pressure of shale increases with increasing foam injection flow-rate due to the penetration of disintegrated gas into the rock (Fig.3). This is caused by the destabilisation of foam when it is in contact with reservoir rock. In addition, the time to achieve breakdown decreases, while the total foam consumption increases with increasing injection flow-rate. For example, an increase of foam injection flowrate from 10 to 70 ml/min causes the breakdown time to decrease by 80% while the foam consumption for fracturing increases by 40%. Therefore, concerning the economic aspects of hydraulic fracturing, low injection flow-rates are much more economical than high injection flow-rates.

Fig.1. Variation of (a) inlet pressure and (b) cumulative energy, with time for water- and foam-fractured specimens (W1 and F1).

Fig.2. Surface topography of foam-fractured specimen (a) 3-D view (b) 2-D view with surface contours (All units are in mm).

Fig.3. Variation of the bottom hole pressure with time for different flowrate conditions

Fig.4. Fracture pattern before and after the hydraulic fracturing with different injection flowrates